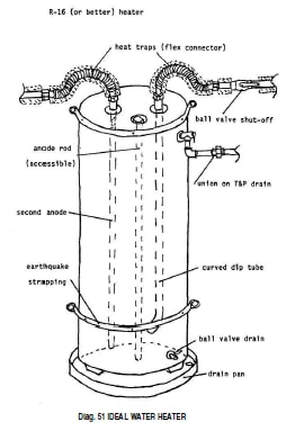

For many experienced plumbers, there really isn't much to replacing a water heater. It's an easy job: just pick up one that matches what's there, maybe strap it in, and leave with the old tank. Whoa. What's wrong with this picture? Just this--it portrays the minimum. Unless you're quite happy with the amount of work you have, the amount of money you make, and the amount of satisfaction your work provides, it's to your advantage to be able to deliver the maximum. When you get jobs because you offer substantial benefits rather than the lowest price, you'll gain long-term, trusting clients and business from their friends, as well. Stand out from your competition. Hot water can change from bread and butter work to something you can actually be proud of. Many clients will gladly pay for superior work. It's true that people often call just shopping for price. (If you look in the Yellow Pages, you'll see most all the ads shouting, "We cost less!" Inadvertently, plumbers' ads have been training consumers to focus on price for years.) Never mind. Stop and talk to these callers. Tell them how YOU install a heater. Explain how the extra things you do will save them both money and worry because the heater will be safer, perform better, and last much longer than an ordinary installation. Let them know that you can provide simple, ongoing maintenance to at least double the life of their new heater. In most cases, you can keep their heater going for as long as they live there. (Some of our clients' heaters are more than fifty years old.) Many people will be very interested in what you have to say. Well, what do you need to know to provide this superior installation and follow-up maintenance? It's useful to start with an understanding of the things that make a water heater fail. Most people have only a partial picture of what goes on inside a water heater that affects its longevity. Corrosion, pressure, and heat are the three things that can do a heater in. CORROSION How do you control corrosion? The sacrificial anode is the magic wand. All glass-lined tanks have at least one. An anode is a magnesium or aluminum rod suspended inside the tank. It acts like a weak battery when the tank is filled with water. A slight current is generated between the anode and the steel tank (cathode). The current prevents rusting at any exposed steel parts such as welds, fitting penetrations, and pinholes or cracks in the glass coating. The glass does a good job of protecting the tank, but without an anode, a tank would last only a few years. You don't need to buy an expensive ten-year tank to install a high quality heater. Longer warranted tanks have either a second anode or a more substantial single anode. When you put a new heater in, go ahead and buy a five-year tank. Then transform it into the equivalent of a ten-year tank at less cost by adding a second full-length magnesium anode in the hot outlet. (This combination rod has the magnesium suspended below a plastic-lined steel nipple.) Anodes corrode away over time. In normal waters the anode should be checked every three to five years. If you can see six inches or more of the rod's core wire, replace it. If the tank has a second rod, you can wait longer, checking every four to six years. Softened water is another story. It's more conductive than normal water and forces anodes to corrode more quickly. Over-softened water can completely consume an anode in six months. Don't ever soften water down to zero hardness. Instead, leave 60-120 parts per million of calcium hardness in the water. That's better for metal piping, as well as anodes. You can fight corrosion at plumbing hook-ups, too. Just as magnesium anodes corrode to protect steel, steel will corrode to protect brass and copper. Avoid using brass and copper in a steel tank. Instead, use plastic-lined nipples for all hook-ups, such as putting a brass valve or copper flex-line on steel pipe. This prevents damage to the steel. When you connect to the lined nipple with a copper flex-line, you've made a dielectric union that doesn't expose any steel to the water. Now it won't fill up with rust and cause trouble. Sometimes plumbers have trouble with leaky flex-lines. The problem is caused by the rubber washers in the ends of the lines. Heat makes them shrink, and they may leak after a year or so. Go back after six months and snug up the flex-lines, or instruct your client on tightening them. After it's been done once, the flex-lines will perform nicely long term. PRESSURE Even though they're rated at 150 pounds, water heaters are happiest with fifty to sixty pounds of pressure in them. Both higher pressure and greatly fluctuating pressures can damage the glass lining over time. You've probably heard the crackling noise a new heater can make as it's filled and finishes pressurizing. That's the glass breaking as the steel stretches under pressure. Anodes have to work overtime in such tanks and won't last as long. And if you hear a tank groan when water is run, take out your 0-200 psi pressure gauge (with a female hose adapter attached) and check pressure at the heater drain. You'll find it's too high. If you flush sediment from such a tank, you may see blue glass shards coming out the hose. Pressure can peel the glass lining off so it's no longer protecting the steel. Solving pressure problems means both helping your clients and gaining a little more work for yourself. You may need a pressure reducer, expansion tank, and/or relief valve to take care of a high pressure problem. Carry your pressure gauge with you the way a termite inspector carries an ice pick. Use it to troubleshoot and locate problems. Another pressure problem is water hammer. We've seen water hammer collapse the flue in gas heaters, and that definitely affects their performance! Sometimes water hammer is eliminated just by getting high pressure back down to normal. Otherwise, install water hammer arresters just upstream of any quick-closing valves to quiet down noise. HEAT Heat is the third cause of water heater demise. When temperatures exceed 160 degrees, the glass lining of the tank begins to dissolve. Temperatures higher than 1000 degrees have been measured under heavy sediment build-up in gas heaters. You can control sediment to prevent heat damage and subsequent tank rusting. You've probably heard the rumbling or popping sounds fuel-fired heaters can make. The noise originates in the sediment, and it seems to be caused by steam. Water overheats in the sediment and expands into bubbles of steam. When these bubbles hit cooler water, they instantly collapse to a tiny fraction of their former steamy selves. (A pound of water is about 1/1700th the size of a pound of steam.) This implosion creates a shock that we hear as rumbling or popping (or a burglar, or a freight train--we've heard some colorful descriptions.) You can check to see if a tank has sediment. While the heater is firing, turn on a tap (either hot or cold) to lower the household water pressure. If there is a sediment build-up, you will hear the rumbling noise when the tap is opened. It will quiet down when you've closed the tap. At 50 psi water boils at 298 degrees (the higher the pressure the higher the boiling point). If there is sediment, the water trapped in it is overheating. Running a tap will lower the boiling point, so that the overheated water will flash into steam, making the noise we hear. A clean tank can't make that noise. You need to get rid of the sediment to protect the tank from overheating. Much sediment can be flushed out if there's good water pressure and flow. You'll need a couple of new parts to make the flushing effective. First, replace that troublesome plastic drain valve with a brass ball valve. Use a lined nipple between tank and valve and put a hose adapter in the outboard end of the valve. To keep the valve from getting too hot, use a nipple at least three inches long. That way, scale won't form on the ball and the seals won't get scored when the valve is used. Voila--no drips! Now you have a large, easy-to-use valve that won't plug up with sediment during flushing. Second, remove the heater's factory-installed dip tube. Replace it with one that's curved at the end. Aim it straight back, away from the drain valve. When the valve is opened, the curved dip tube sends the water swirling around the tank, picking up sediment and sweeping it out the drain. Overheating and noise problems are also caused by aluminum anode debris, as well as calcium sediment. As aluminum corrodes, it's able to produce nearly a thousand times its volume in gelatinous goo. It can make a six-month old tank rumble, creating a complaint you must deal with. So replace aluminum anodes with magnesium rods. (Avoiding aluminum also avoids some serious health problems associated with it.) It's not hard to identify the rods. Aluminum is soft and easy to bend, while magnesium is much stiffer and somewhat springy. Those are the culprits: corrosion, pressure, and heat. Once you've taken measures to solve and/or prevent problems in these areas, expect the heaters you deal with to last a very long time. Since you also want to offer the safest and most efficient heaters possible, look outside the tank next. SAFETY CONCERNS Having a heater that lasts forever is nice, but meaningless if that heater is unsafe. Check out the following items for safety and reliability. T&P The temperature and pressure relief valve is a piece of plumbing most plumbers fear to touch. We're afraid NOT to. If you service a water heater, guess who the authorities are going to call if the tank later overheats and takes off like a rocket? It's you who will be blamed for the plugged T&P. T&P valves need testing at least once a year. They can and do get clogged with debris. While testing sometimes results in annoying leaks, more importantly it can show that the valve no longer has the ability to keep the tank from blowing up. If the valve does not allow full flow or if it doesn't re-seat, replace it. In our area, about one of four valves doesn't work correctly. It's useful to hook up the relief valve with a union or flex connector as you run the line to a safe place. The union makes future checks much easier. Venting Vents can do a variety of unsafe things. They fall off, fill up with mortar from brick chimneys, get their caps plugged or pushed down, and they get installed with too much run and not enough rise, so draft is poor. In addition, heaters are put into rooms with slight negative air pressure, so that air is sometimes or always getting sucked down the vent pipe, spilling combustion fumes. Wait, there's more. Inadequate slope allows condensation to eat holes in the vent. Vents are run past wood, scorching it. And then, people pile boxes, plastic bottles, and other flammables next to hot vents. Take a good look at the venting of heaters you install or service. Check to be sure that if a vent goes into an attic it also comes out. When the heater is fired up, spillage around the draft hood should be for only a few seconds. If combustibles are stored too near the heater or vent, talk to your clients and make a note on your invoice. If you see evidence of back-drafting, let them know about carbon monoxide detectors. Clients will appreciate your looking out for their safety. Earthquake Protection Even with the large earthquakes of the not-too-distant past and with the codes mandating specific strapping, we still see new heaters installed with inadequate bracing. Quakes WILL happen. We just don't know when. Be sure your heaters are correctly strapped. Leak Protection Probably not life-threatening, leaks can cause a whole lot of costly damage. So look around each job site to see what would be damaged if the water heater leaks. (And if it leaks for three weeks while the owners are in Tahiti?) If nothing will be hurt, you don't need a drain pan. Otherwise, you do. The pan also needs a drain line that's actually hooked up. (We've seen drain pan outlets just covered with duct tape, out of sight behind the heater.) There are some interesting devices on the market now which are designed to shut off water supply to the heater if it starts leaking. Another option which might give your client peace of mind is a water alarm in the drain pan. To avoid false alarms or damage to the heater, run the drain line from the T&P out separately. Lines from both the T&P and drain pan should end where the homeowner will see them and be alerted to any leak. Energy Efficiency Recent energy difficulties have raised awareness in consumers and plumbers alike. The need for efficiency in hot water systems is better understood and accepted. Correct heater sizing is one of the most important factors in the energy picture, but it's often overlooked. If you're called to replace a heater, don't automatically put in the same size. Ask some questions. Did the old tank provide adequate hot water? Have new fixtures been put in (low-flow showers, aerators, front-loading washing machines)? Check older showerheads. If you find an old 8 gpm showerhead, you can probably reduce the heater size by installing a low-flow shower. The energy savings will quickly pay for it. Smaller heaters always have a higher energy factor, due to lower heat loss. Whatever the size, heaters with good insulation cost little more than their thinner counterparts. If you're installing a new heater and can get those extra inches of insulation to fit into place, your client will thank you for it. Tanks with R-16 insulation are readily available these days, and in popular sizes they can even cost less than the old standard R-8 heaters. Blankets aren't nearly as good as built-in insulation. Even the best blanket won't insulate your heater to R-16 (and you should not cover the top and lower portion of the heater). Another drawback is that blankets cover up safety and operating instructions; they can also hide evidence of leaks. Go beyond the tank itself and install heat traps on the lines above the tank. Avoid the chattering ball type and install silent ones; you can make your own by using long flex connectors to make an upside-down U in the lines. Heat traps prevent errant BTU's from wandering away. In addition, insulate those plumbing lines. Insulate as much hot line as you can and the cold line back five feet from the heater, if possible. Use 3/4" thick foam; it takes no more effort than putting in thinner stuff, and it does a much better job. Leave the ends of flex-lines or other unions uncovered, as you may need access and you don't want hidden leaks. THE END RESULT It's within your power to give your clients the most satisfactory water heating experience they've ever had. Long service life, safety, and efficiency are intertwined, and serviceability (the things you've built in which make the heater easy to maintain) overlaps all three areas. If you don't set up a heater so it's easy to service, maintenance probably won't happen. Forget trying to offer the cheapest heater. Instead, educate clients a little so they will let you give them an outstanding job. They'll be happy you took the time to show them a better way. Yours, Larry

1 Comment

|

Larry Weingarten

Looking back over my working life of 50+ years, it seems clear that self sufficiency has always been the best way for me to be useful. Now, mix in a strong interest in water in its many forms and the wide world of animals and you'll know what's important to me. Archives

January 2023

Categories |

Copyright © 2014 - 2023

All Rights Reserved

All Rights Reserved

RSS Feed

RSS Feed